| |||||

|

|

||||

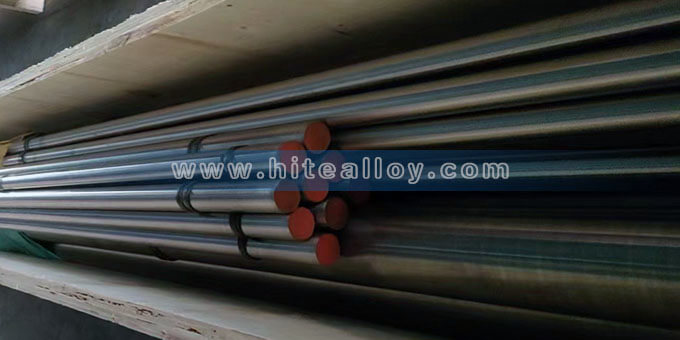

The commonly used product grades for Inconel625 include China (GH3625), the United States (N06625/NS336), and Germany (2.4856). It is a high-strength and corrosion-resistant alloy. Today, a batch of orders were produced and recorded, and the product was displayed in conjunction with its application field.

1. Petroleum and natural gas industry: Inconel 625 alloy is widely used in the petroleum and natural gas industry. It is used to manufacture equipment such as pipelines, valves, tanks, and heat exchangers under high temperature and pressure, which can resist corrosion and erosion in high-temperature environments, ensuring the reliable operation of the equipment.

2. Chemical industry: Due to its excellent corrosion resistance, Inconel 625 alloy is widely used in equipment such as reactors, distillation towers, storage tanks, and pipelines in the chemical industry. It can resist the erosion of corrosive media such as strong acids, alkalis, and salts, ensuring the safe operation of chemical equipment.

3. Aerospace industry: Inconel 625 alloy also has important applications in the aerospace field. It is used to manufacture high-temperature and high-pressure components such as engine components, combustion chambers, turbine blades, and nozzles, capable of withstanding extreme working conditions and providing reliable performance.

4. Nuclear industry: Inconel 625 alloy is widely used in the nuclear industry. It is used to manufacture key components such as nuclear fuel tubes, heat exchangers, and valves in nuclear reactors, and can resist the erosion of high temperature, high radiation, and corrosive media.

View the chemical composition of Inconel 625 ›