| |||||

|

|

||||

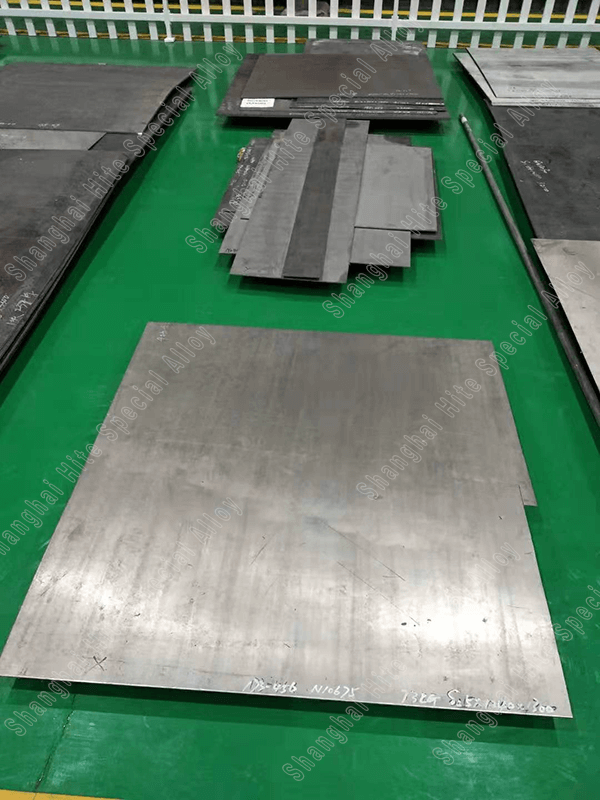

Hastelloy X alloy is a high-performance nickel based high-temperature alloy known for its excellent corrosion resistance and high-temperature strength. This alloy is mainly composed of elements such as nickel, chromium, molybdenum, etc., with nickel content accounting for more than 30%, which endows it with excellent corrosion resistance, especially in high temperature and high pressure environments, it can effectively resist corrosion such as oxidation and vulcanization. Hastelloy X alloy also has the advantages of high temperature strength, good fatigue resistance, and excellent oxidation resistance, which make it widely used in aviation, aerospace, petrochemical and other fields.

In the aviation industry, Hastelloy X is used to manufacture high-temperature components of aircraft engines, such as combustion chambers, turbine disks, etc. In the aerospace field, it is also used to manufacture high-temperature components for rocket engines. In the petrochemical industry, Hastelloy X is used to manufacture high-temperature oil and gas pipelines, valves, and other components. These application fields have extremely high requirements for the high-temperature strength and corrosion resistance of materials, and Hastelloy X alloy perfectly meets these needs.

The production process of Hastelloy X alloy includes melting, casting, heat treatment and other stages, among which the element content needs to be strictly controlled during the melting process to ensure the stability of the alloy. Casting adopts vacuum induction furnace melting to ensure the purity of the alloy. During the heat treatment process, multiple solid solution treatments and aging treatments are carried out to obtain the best mechanical properties.

Details or business needs: Hastelloy X(UNS N06002) >