| |||||

|

|

||||

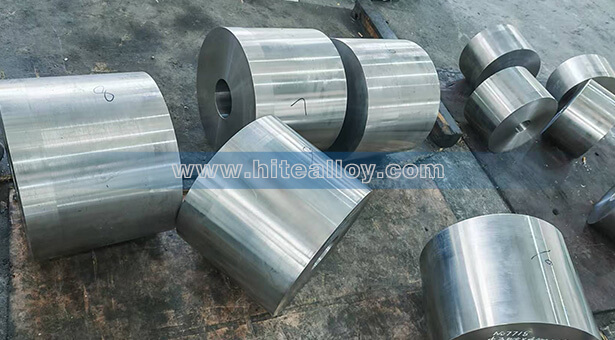

ASTM B637 solution treated and precipitation hardened Inconel 718 bigger forgings get ready on time for old customer, UT 100% passed, chemical and hardness and mechanical properties all passed according to B637 standard too.Hite special alloy shipment record.

The core process of Inconel 718 large forgings is forging. Large size ingots (usually produced by vacuum induction melting+electric slag remelting or vacuum induction melting+vacuum arc remelting processes to achieve high purity and uniformity). After the billet is opened, it is processed into a forged piece that approximates the final shape of the part through forging or free forging.

Inconel 718 is commonly forged using isothermal forging for large 718 forgings with complex shapes and high deformation resistance. The mold and billet are kept at the same high temperature (usually below the gamma 'dissolution line of the alloy) and forged at an extremely low strain rate.

Inconel 718 alloy's excellent comprehensive performance (high temperature strength, corrosion resistance, fatigue performance) combined with forging processes (especially isothermal forging) is used to manufacture key structural components that can withstand extreme environments (high temperature, high pressure, high stress, corrosion).